Pressure regulator expander

Keywords:

Pressure regulator expander

Category:

- Product Description

-

Independent intellectual property rights

The superior performance of the pressure-stabilizing expander has been recognized by more and more designers and users. Based on years of equipment use, our company has developed a second-generation product with even better performance by leveraging strengths and compensating for weaknesses. Its energy efficiency, service life, and system integration stability have all been significantly improved compared to the first-generation product.

Pressure-stabilizing expander unit

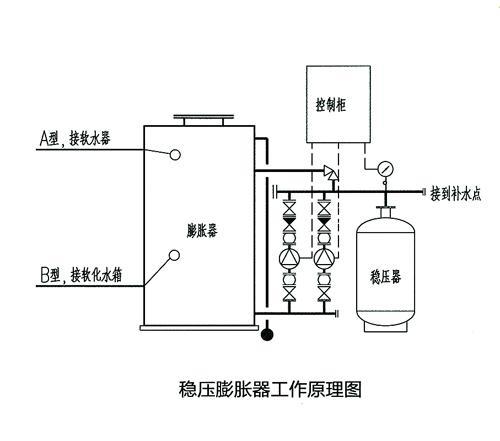

The pressure-stabilizing expander is a new type of pressure-stabilizing and expansion equipment that integrates a pressure regulator, expander, and make-up pump. This equipment is suitable for heating, air conditioning systems, and various circulating water systems. It has pressure-stabilizing, expansion, and make-up water functions, effectively stabilizing system pressure, and its performance is superior to that of a floor-standing expansion water tank.

Computer intelligent control

This product uses an advanced ultra-small PLC to replace the traditional relay control. It features an integrated human-machine interface and host, with an intuitive and easy-to-understand interface. It has dual digital displays for input/output and real-time clock functions; it has dual-pump alternating and simultaneous operation functions, low-water level shutdown protection, phase failure, overload, and undervoltage protection functions. Remote control can also be implemented according to user requirements.

Eliminate expansion tanks

Ordinary floor-standing expansion tanks rely on the expansion and contraction of capsules to accommodate system expansion volume. The effectively usable volume of the tank is only 20-30% of the total tank volume. The tank is quite large. However, Jinzel's pressure-stabilizing expander uses special technical measures, and the volume utilization rate can reach 70% or more. The overall volume and height are greatly reduced, saving 50-70% of floor space, and it has more complete functions and superior performance, completely replacing floor-standing expansion tanks.

Complete unit factory assembly

Ordinary floor-standing expansion tanks are large in size, transported in parts, and assembled on-site, increasing installation difficulty and reducing equipment reliability. However, because the pressure-stabilizing expander is smaller in size and shipped as a complete unit, on-site installation only requires connecting the inlet and outlet pipes, making installation simple, fast, stable, and reliable.

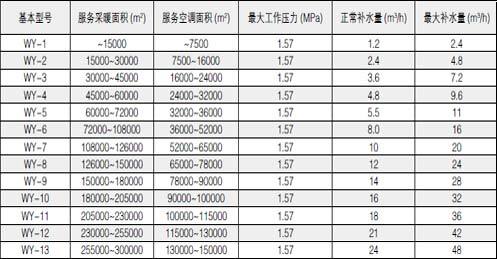

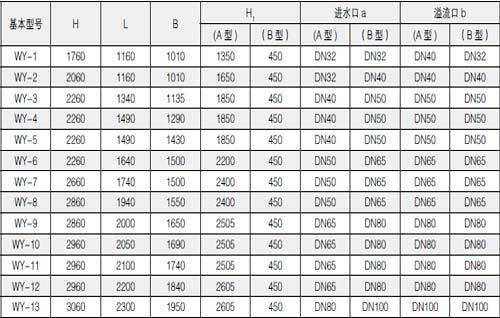

Product Basic Performance Table

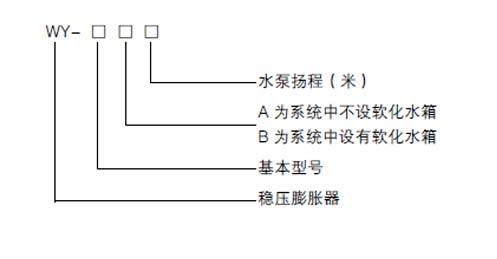

Model Description

Model Selection Description

Select the basic model according to the make-up water volume of the closed system; there is no need to consider the system expansion factor.

Determine whether a softener tank needs to be set up based on the output of the softening equipment in the system. If the output can be guaranteed without interruption, a softener tank is not needed, and type A can be used; otherwise, a softener tank needs to be set up, and type B pressure-stabilizing expander should be used.

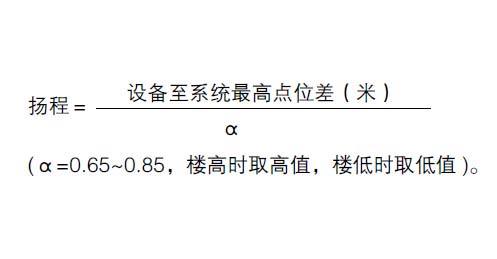

Select the make-up pump head:

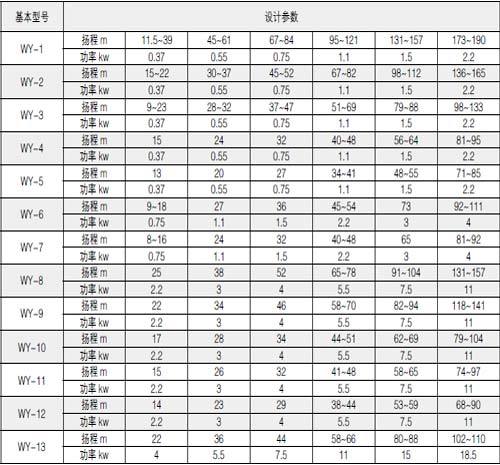

Make-up Pump Head and Power

Note: The head listed in the table is only a value selected according to the water pump characteristic curve and does not represent all operating conditions.

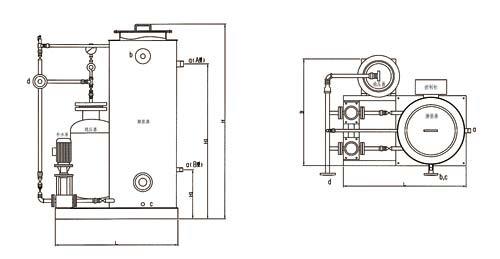

Outline Diagram

Installation Dimensions Table

Installation Precautions

● When using this equipment, the water temperature should not exceed 95℃. The pump room should have good ventilation, and the winter room temperature should not be lower than 0℃ to ensure normal operation of the equipment.

● The inlet of type A is connected to the tap water or the outlet of the softening equipment; the inlet of type B is connected to the outlet of the softening water tank; the overflow and drain pipes are connected to the sump.

Remarks

● The table lists commonly used specifications. If the specifications exceed the range of this table, our company can also manufacture them according to the design or user requirements.

Ordering Instructions

● Please be sure to specify the model (Type A, Type B)

● Please specify the required make-up pump head and flow rate parameters

Related Products

Contact Us For Quotation

*Note: Please be sure to fill in the information accurately and keep the communication open. We will contact you as soon as possible.